YOKI OP-1900 TILT-BACK TYRE CHANGER

SPECIFICATIONS:

-

Outside clamping: 10” – 24”

-

Inside clamping: 12” – 26"

-

Maximum wheel width: 16 inch

-

Maximum wheel diameter: 1120mm or 44 inch

-

Working pressure: 8-12 bar

-

Bead breaker force: 2800K

-

Power supply: 240V

-

Freight dimensions:

L 1165mm W 805mm H 1020mm W 325KG

Main Features

-

Double-structure cabinets

-

Tilt Back column design and three assist arms.

-

18mm Aluminum-Iron Alloy Dual-Inlet Separation Cylinder

-

Pneumatic horizontal and vertical arm locking system

-

Adjustable bead breaker shovel

-

18 months warranty

Multi-angle adjustable press shovel design.

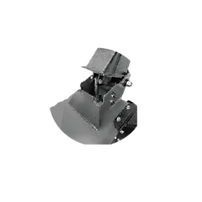

14 mm thick hub chuck assembly with fine-adjustment function for chuck opening/closing dimensions. The chuck jaws can be precisely controlled at any position, enabling secure wheel clamping and preventing accidental damage.

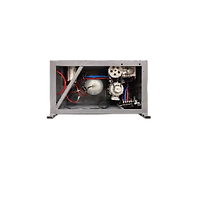

The foot-operated pneumatic valve piston rod assembly is constructed from S304 stainless steel, featuring a smooth surface with excellent corrosion resistance for extended service life. The drawer-style control unit has a simple structure, enabling quick and convenient maintenance and repair.

Top quality aluminum motor with all-copper windings delivers superior heat dissipation, reduced energy loss, and high power output. The 180mm diameter dual-inlet bead breaker cylinder features a fully sealed design, operates efficiently even at low air pressure, and ensures extended service life.

The modular casing is constructed from CNC-formed steel panels and robot-welded with concealed seams for a sleek appearance.

The tower-style column base and casing are constructed with fully integrated welding, ensuring exceptional load-bearing capacity, structural stability, and reliability during high-intensity operations. A tapered bushing with bi-directional locking mechanism prevents long-term loosening.

The rear-tilting upright arm design creates expanded operational space above the hub chuck, preventing accidental damage during wheel clamping. The sliding roller mechanism incorporates a 55 x 55mm square steel push-pull arm with CNC precision grinding, maintaining unilateral clearance under 0.5mm. This ensures the pry head displacement remains within 3mm during tire mounting/demounting operations.